What do the Cubes go through before reaching your home?

by Alja Isakovic

Ever wondered how your CubeSensors are made? What kind of tests they go through before we ship them out?

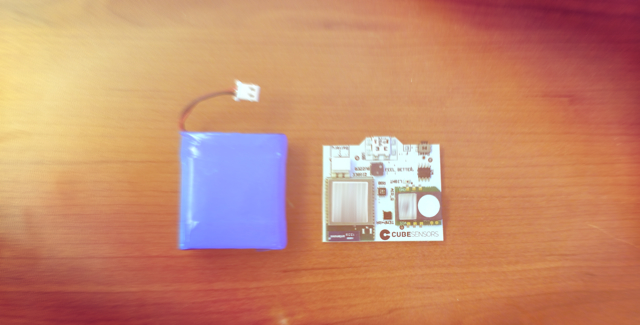

It all begins with a small, white printed circuit board (PCB), packed with sensors. We attach a battery to each board and set it up with a special firmware that makes sure to “burn” the Cube’s air quality sensor for 3 – 4 days. This makes sure the sensor self-calibrates faster in your home.

After that, another setup firmware is loaded, which quickly charges, discharges and recharges the battery on the Cube. This helps us to identify batteries that don’t perform as expected and any sensors that don’t work properly. The whole process takes about 2 days for each Cube.

Once the Cube candidates pass this initial test, we load them with the almost final firmware, put them on charge again, and let them automatically update to the firmware we’ll ship them with. During this phase, we pay even closer attention to the measurements, sent by each of the sensors. If anything appears off, the Cube can’t connect to our crowded ZigBee network or doesn’t go through the update, we take the Cube out of the process for a closer inspection.

For the majority of the Cubes that make it through setup and the update, it’s now finally time to actually become Cubes. We glue all the parts together, and let the Cubes settle over night. The next day, we charge them one last time and do one final check of the measurements before cleaning and packing them up. After that, we just make sure they are turned off for their last journey to your home or office, where they are immediately ready to start making you feel better.